1.

Remove air filter and cover. This uses 2 over-center

clamps

2.

Remove air filter base plate from intake manifold (3

bolts, 10mm socket)

(this step is to

make removal of the aft most fuel injector fuel line possible)

3.

Remove alternator from bracket and set aside. Leave

wires connected. I figure most people reading this can find the alternator.

4.

Remove the cooling water high temp switch wire (unscrew

the ring terminal from sender at front of thermostat housing, on top of fresh water

pump, on top of front of engine)

5. Yanmar seems to have made this engine first as a sea water cooled engine, so this step wasn't required because the engine didn't have a fresh water pump. Otherwise why make it so hard to remove the injection pump without removing the fresh water pump?

The fresh water cooling system will leak water all over the engine, so drain the fresh water system using the small valves at the aft end of the heat exchanger near the exhaust elbow and on the side of the block.

The fresh water cooling system will leak water all over the engine, so drain the fresh water system using the small valves at the aft end of the heat exchanger near the exhaust elbow and on the side of the block.

Anyway, remove the fresh water pump. There are 3 hoses connecting

the fresh water pump so loosen the hose clamps for each of these. (If these hoses are

old and swollen, consider replacing them as preventative maintenance.) There are

4 bolts, 12mm wrench holding the pump in place. Do not loosen the smaller 10mm head bolt. These bolts are

behind the water pump pulley so you cannot use a socket wrench and you will only loosen

the bolts, not remove them.

6.

Remove throttle lever nut and remove throttle lever

(where the throttle cable connects). 12mm socket. But do not disconnect the throttle cable

from lever.

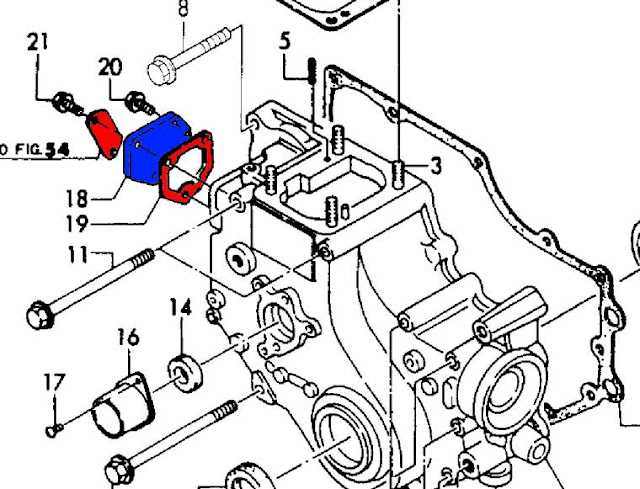

7.

Remove the small access plate from stbd. side of

injection pump (right in front of the throttle lever). (3 bolts, 10mm socket).

This will also remove the throttle stop screw on a separate plate marked in red.

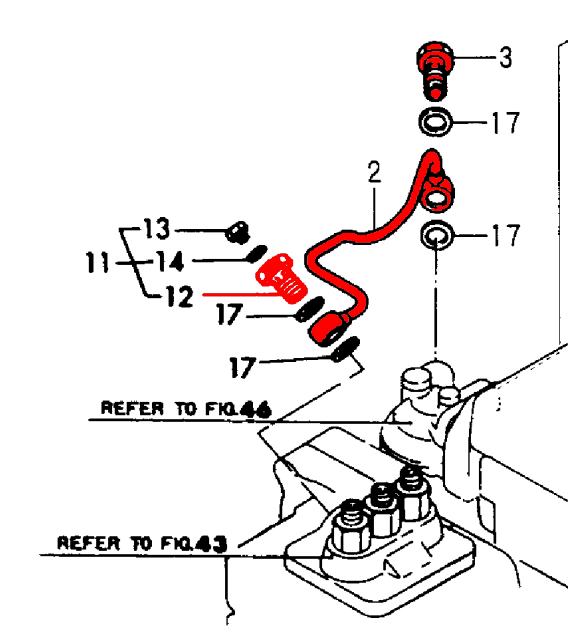

8.

Remove the fuel line connecting the engine mounted

fuel filter to the injection pump (14mm wrench). There is an additional engine

mounted bracket that requires removal (12mm socket) on my engine. Yanmar parts

books shows several different types of fuel lines so just remove the one

supplying the injection pump.

9.

Getting closer now. Wipe up any dirt or debris around

the fuel injection pump. Remove the 3 high pressure fuel lines from the pump

and the fuel injectors. Loosen the forward most cylinder line / forward most

connection on the pump and then proceed aft in turn. Use a 17mm wrench.

10.

After all high pressure lines are loose, remove the two

clamp fittings (shown in blue above) holding the lines together and to the engine (10mm socket, 4 bolts

total)

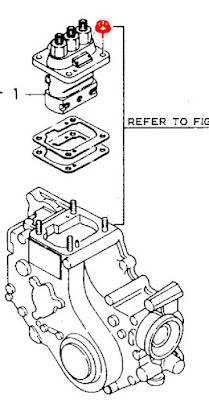

11.

Loosen the nuts holding the fuel injector pump to the

engine block. The pump will be loose but still held in place.12mm socket with extension. You might need to

break the seal between pump and mounting flange by prying gently with a

screwdriver at first.

12.

Put a finger into the side access hole you uncovered in

step 7. Feel for the throttle lever that pulls the fuel injection pump rack pin

forward and back. You need to slide that lever backward or forward until it

pulls free of the rack pin as you lift the pump slightly.

12.

Put a finger into the side access hole you uncovered in

step 7. Feel for the throttle lever that pulls the fuel injection pump rack pin

forward and back. You need to slide that lever backward or forward until it

pulls free of the rack pin as you lift the pump slightly.Now lift the pump while moving the rack pin forward or aft. There is a opening in the mounting flange shown on left picture below that the pin needs to pass through. Pull the pump up while simultaneously moving the pin forward and aft and the pump should come free. You do not need to force the pump if it is free of the flange. I repeat - don't force the pump. If comes free very easily if you have the rack pin lined up with the notch in the flange.

13. Do not lose the thin shims between the pump and

mounting flange. You will need these for reinstallation. Mine had 3 shims.

When reinstalling the injection pump Yanmar specifies “Screw Lock Super 203M” between the shims. I think it’s pretty close to a blue Loctite 242 so that’s what I used. Remember that the thickness of these is critical to injection timing – so don’t use a thick silicone gasket sealer when re-installing. The governor case below is only splash lubricated with lubricating oil so it won’t take much to seal the pump to the mounting flange.

When reinstalling the injection pump Yanmar specifies “Screw Lock Super 203M” between the shims. I think it’s pretty close to a blue Loctite 242 so that’s what I used. Remember that the thickness of these is critical to injection timing – so don’t use a thick silicone gasket sealer when re-installing. The governor case below is only splash lubricated with lubricating oil so it won’t take much to seal the pump to the mounting flange.

- Evan